Mill internal

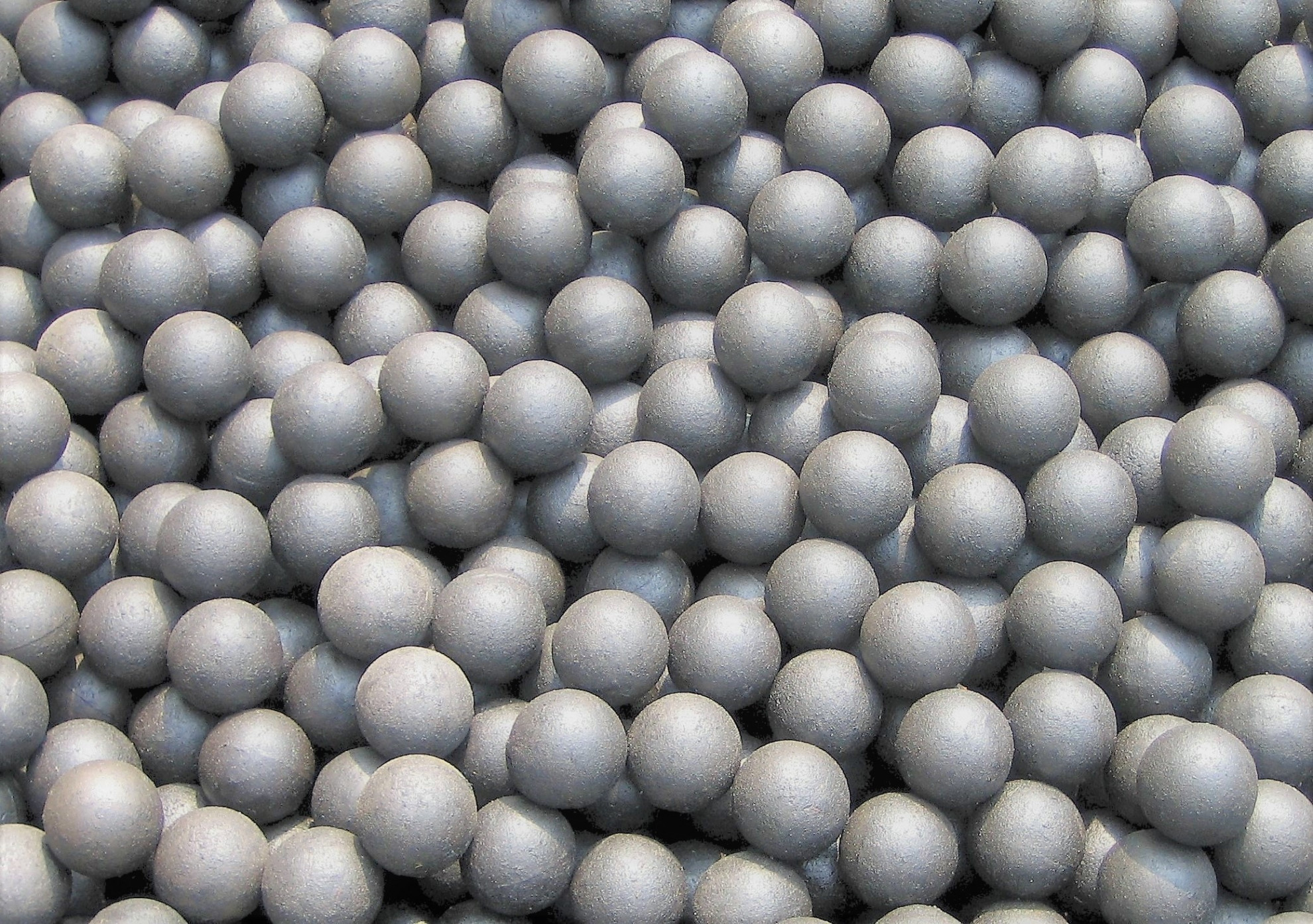

Steel ball

We supply grinding balls for the mining, cement, steel plant, power plant, aggregates etc industries. According to the working conditions, we could supply casting, forged, high Cr, low Cr, high C, low C grinding balls.

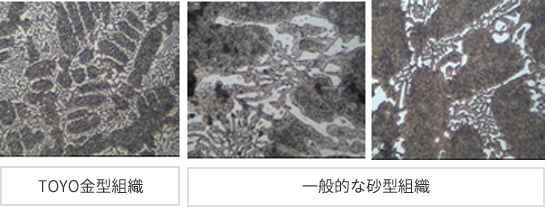

For the casting balls, we are using our unique metallic molding casting process, which will have higher microstructure density comparing to normal sand molding line. Adding unique heat treatment technology, our balls will offer lower wear rate.

| Main Grade | Process | Cr(%) | 硬度(HRc) | サイズ(mm) |

|---|---|---|---|---|

| UR | Casting | 25-29 | ≧60 | 15-90 |

| ER | Casting | 19-23 | ≧60 | 15-90 |

| SR | Casting | 16-19 | ≧58 | 15-100 |

| RDH | Casting | 10-13 | ≧58 | 15-100 |

| RD | Casting | 10-13 | ≧50 | 30-100 |

| D | Casting | 1-3 | ≧48 | 25-120 |

| ST | Forrged | — | — | 20-140 |

※シルペッブ各種

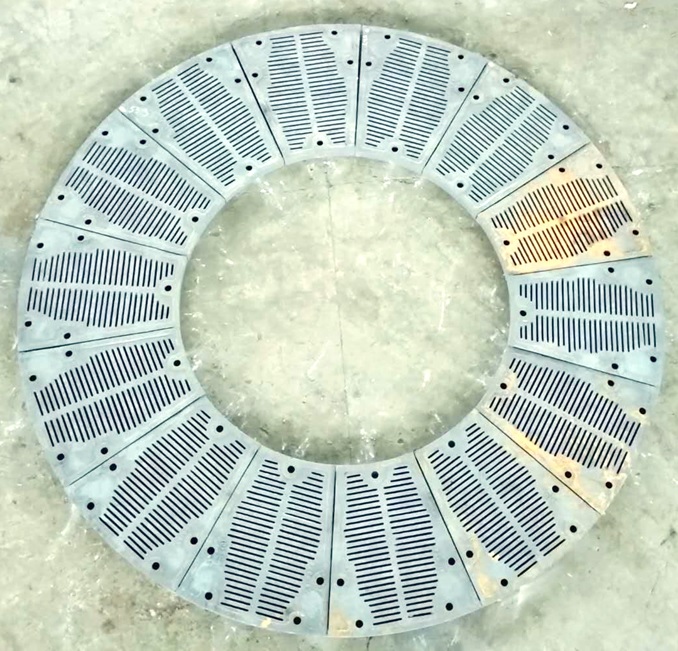

Liner, grate

Liner and grate plays an important role in the mill. We design the shape and alloy to reach the optimal function. In 1st cpt , we design its lifting power to have the best crushing efficiency. In 2nd cpt, we design its classifying power to have the best grinding efficiency.

We believe that with our ball charge gradation design will improve the mill production and reach higher efficiency.